A few years back when I was in the mass manufacturing business designing parts and production lines. Jigs and fixtures were always needed but often expensive and time consuming to make. As a consequence they were not used as often as they should have been. Current 3D printing in engineering materials would have certainly made this easier and faster, improving production efficiencies and safety.

In today’s post we are showing just one possible use for 3D printed jigs we have been involved with recently, that is conformal coating masks for the electronics’ industry:

Conformal coating is applied to circuit boards to protect them from moisture and other contaminants in the environment, some typical industries that use conformal coating would be appliance manufacturers (Washing machine or dish-washing control boards) or in military applications. Boards are sprayed or dipped in a material that insulates and protects the electronic assembly.

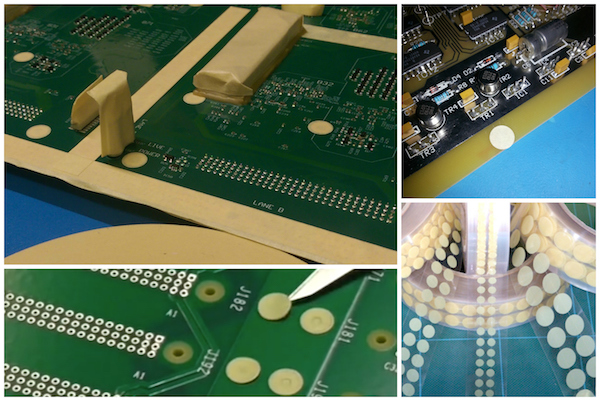

But not everything should be coated, for example the connectors need to have clean surfaces and be absolutely free from any insulating coating. This is the problem, solutions can be time consuming and not always effective, for example manually applying tape or little caps as below:

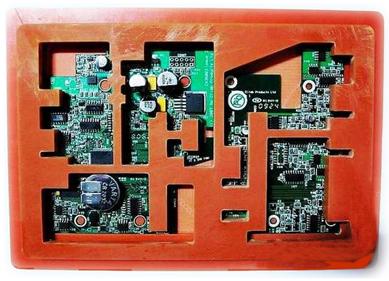

Another option (If there is enough volume to justify the cost) is machining the conformal mask as below, however for small runs this is not economic and tends to curb design flexibility as once you have paid for these jigs you won’t want to change them:

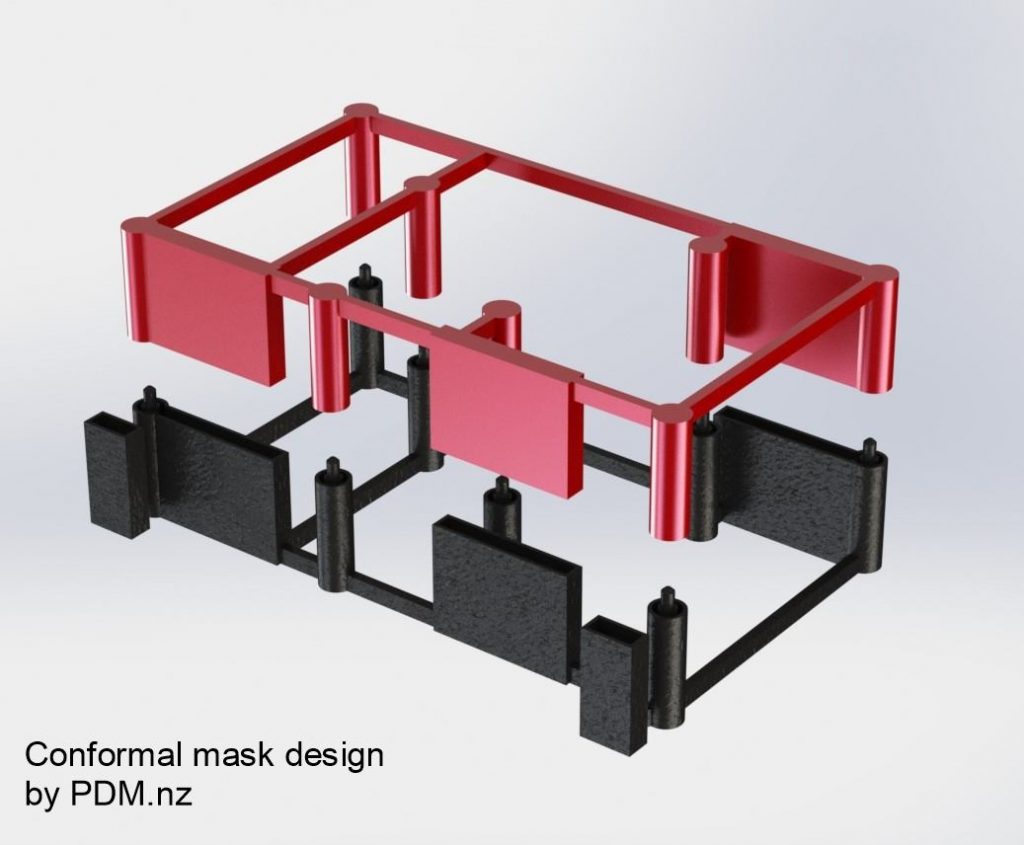

If you or your company knows these issues only too well, Palmer Design & Manufacturing may be able to help you. We have just started manufacturing conformal coating masks that are one piece jigs that fit over all connectors at the same time:

Produced in an ESD safe material (semi-conductive plastic that dissipates static electricity) and at a fraction of the cost of machined covers, these jigs can be made in a few days offering great design flexibility and professional options for low volume manufacturers.

Let us know if we can help.

Andrew Palmer

Director

Palmer Design & Manufacturing Limited